On January 20, Nona Deprez, the European Union's ambassador to Nepal, had a busy day. The trip began at midday with a visit to the brick factory and ended with an inspection of a building under construction. However, the time and effort ambassador Deprez put in were very well worth it because it was a watershed moment in Nepal's brick-making history, with the switch from traditional Nepali brick to energy-efficient hollow brick.

Hosnna Brick Factory, Harisiddhi, 10 kilometers south-east of Kathmandu, was selected from among 200 brick factories to host a program and welcome high-level guests. It was a significant day in the factory's 20-year history because the factory was preparing to say goodbye to Nepal's century-old emissions-laden traditional clay brick and formally start mass production of different sizes of energy-efficiency hollow bricks.

The day was momentous to Kalpana Shrestha, a landlord at the opposite side of Lalipur in Gwarko, close to Ring Road, Koteshwor. The mayor of Lalitpur Metropolitan City (LMC), Chiri Babu Maharjan, the envoy of the European Union to Nepal, Nona Deprez, together with leaders and representatives from the federal, provincial, and local levels as well as private sector brick producers, have all been welcomed to Shrestha's home, which is currently undergoing its final stages of construction.

The program was frantic for Mayor Maharjan, Ambassador Deprez, and other dignitaries, but the promotion of hollow-fired clay brick was initiated in support of Nepal's efforts to cut emissions and conserve energy. The ultimate goal of the initiative is to lower emissions levels globally.

In her address during the gathering, Ambassador Deprez emphasized its significance. "I am encouraged after engaging in activities. Everywhere in the world, hollow brick are used. The presence of individuals from various governmental tiers and organizations makes me very pleased. It's good to note that this project coordinates with other projects. I'm hoping for synergy rather than overlap or gaps.”

"Several different groups and individuals have been engaging on this initiative at different levels. The possibility that this initiative will support change gives me enormous hope. I considered it a positive move because brick producers, local and federal agencies, and the Alternative Energy Promotion Center were collaborating together, " said Ambassador Deprez.

"It all boils down to thinking and mindset change. However, altering one's perspective is not simple. In my conversations with people and what I have witnessed today, I feel encouraged. “

"What is needed right now is to enhance consumer knowledge that this brick is in their long term interest as a citizen since it impacts the air we breathe and our health. In the end, it comes down to how well our shared planet, on which we all reside, is doing. We would all gain as citizens if we can each do our small part in reducing air pollution and harmful fuel efficiency," according to Deprez.

The mayor of LMC, Chiri Babu Maharjan, has said that LMC will opt to push the usage of hollow brick in building construction throughout LMC, expressing support for ambassador Deprez's stance. "On behalf of the citizens of Lalitpur Metropolitan, I would like to thank the European Union and Ambassador Deprez for picking our region to kick off this historic initiative to revolutionize brick production in Nepal. We are thrilled to contribute to the worldwide green movement," stated mayor Maharjan.

Mayor Maharjan announced, "I will make all necessary steps to enforce the use of only hollow brick as LMC is building a massive new extension building."

Tour to Brick Factory

Despite its many advantages, local customers have not yet adopted a liking to hollow brick. To broaden the use of the hollow bricks, BEEN plans to start a promotion campaign.

Ambassador Deprez stayed for more than two hours in a brick factory inspecting, observing, and discussing about many aspects of hollow bricks, such as the market, the manufacturing process, and its role in reducing emission. The ambassador asked a variety of questions about the brick's manufacturing, marketing, and overall impact on energy efficiency and the environment during their discussion.

The Hosnna Brick Factory was windy, noisy, and dusty, but the guests and visitors of the launching programs eagerly observed the event intended to alter Nepal's brick-making practices.

The ambassador and visitors were briefed by Suyesh Prajapati, BEEN Team Leader, on the technical, market, and contributions of hollow bricks to emissions reduction in urban settings. Prajapati explained the complete process of creating hollow bricks in the factory and their application on the construction site with the assistance of his colleague Engineer Sanu Babu Dangol. "As part of the launch campaign, we looked at how hollow bricks are made at the Hosanna Brick Factory and how they may be used in a residential building that was still under construction.”

Jyoti Joshi, the deputy director general of the department is accountable for standards and metrology in Nepal, gave an update on the hollow brick Nepal Standard.Joshi said, "We already have started the process to convert Nepal Standard to hollow brick.”.

The ambassador, mayor, and other attendees were briefed by the factory owner Krishna Awale and his son Shyam Kazi Awale on the various stages of brick manufacturing, the market, and conformity assessment.

The Mayor of LMC Maharjan voiced his full support to make this project successful when serving in Bungmati and Pilachhen during his first term. They worked closely together to complete initiatives funded by the European Union.

Mayor Maharjan frequently interrupted the briefing to question how LMC could assist the cause of making complete brick a requirement for building construction.

The LMC's ward chair backed the mayor.According to Ganesh Maharjan, Chair of Lalitpur Metropolitan City Ward 29, the new technology will probably lessen the concern from local residents about the pollution caused by brick kilns.

Shyam Kazi Awale, the owner of Hosnna brick factory, expressed his hope that the hollow brick will eventually replace the conventional brick at the introduction of the brick factor. He claimed that the hollow brick uses less than 60% less coal, 50% less water, and 20% less soil than solid bricks. Awale, who now imports coal daily from the United States and Australia, said of the environmentally friendly brick, "It helps greatly to save the money in importing the coal."

First Building of Hollow Brick

After the hollow brick was introduced at the factory site, ambassador Deprez and mayor Maharjan traveled to Gwarko, Ward No. 9 of the Lalitpur Metropolitan City, to view its use in a multipurpose structure.

The new home, which belongs to Kalpana Shrestha and is currently being finished up, is the first one to be constructed utilizing various hollow brick sizes.

Once it is complete, Shrestha's House will demonstrate the difference between hollow and regular brick in terms of how heat is managed. In this showcase structure, the use of hollow bricks has decreased the structural load by 22.7 tons and the CO2 emissions by 3.36 tons.

This brick kiln has accepted the challenge of making hollow bricks, which may help to reduce CO2 emissions by 225 tons this season and nearly 90 tons next.

In addition to saving energy during construction, hollow brick buildings also use less energy over time. If a room is constructed of hollow bricks rather than solid ones, it is predicted that up to 5% of the energy used for air conditioning will be saved, according to Prajapati. "The creation and use of hollow bricks can drastically lower fuel costs for brick manufacturers, which improves the nation's economy overall. Brick kiln emissions are also decreased by the lowering in coal use."

Ambassador Nona Deprez and the mayor of LMC Chiribabu Maharjan accompanied the owner of the house and the brick factory after viewing how hollow bricks are formed at the Hosanna Brick Plant and touring the Gwarko House that was under construction.

Deprez and Mayor Chiribabu Maharjan of the LMC provided support to the owner of the property and the owner of the brick plant.

Suyesh Prajapati, BEEN Team Leader/MinErgy, demonstrates the advantages of using hollow bricks in a small function.

Similarly, Shankar Bahadur Chand, the President of the Federation of Nepalese Brick Industry (FNBI), emphasized the challenges encountered by brick proprietors.

A vote of gratitude was given by Daniel Neyer, the manager of the University of Innsbruck's BEEN Project.

How does hollow brick contribute

Harisiddhi has been associated with brick production for generations because of the high quality soil and water supply there.

There was also built the first, highly advanced brick factory about fifty years ago. It is the proper choice to select Harisiddhi once more to introduce a new hollow brick technology to replace the century-old clay brick.

"The anticipated yearly average brick production in Nepal is 5.14 billion. The primary fuel used to fire bricks is imported coal from India and other nations, according to Prajapati. "Everything will be reduced by hollow brick. "Hollow bricks are environmentally friendly since they use less energy and clay during production.Thermal comfort is provided by hollow bricks. It keeps the building's internal walls cool in the summer and warm in the winter. A hollow brick is capable of supporting a load.”

According to the ICIMOD study from 2018, 504,750 tonnes of coal are used annually in Nepal to fire bricks.The ability of hollow bricks to conserve clay and fuel is one of their main advantages.

The percentage of hollowness affects fuel savings.According to studies, a brick with 15% hollowness can save up to 24% on clay and up to 30% on fuel (TERI, 2017).

In addition, bricks with tubular hollow cavities have better insulating qualities, which eventually lowers building operating costs.

According to studies, the U-values of a hollow brick wall are up to 25% lower than those of a solid brick wall.If a room is constructed of hollow bricks rather than solid ones, it is predicted that up to 5% of the energy used for air conditioning will be saved.

Use in Nepal

In spite of its numerous advantages, Hollow brick manufacture and use are uncommon in Nepal. It had been used by some people in the past. The mayor of Lalitpur Metropolitan City asserts that he placed a building order for hollow brick in 2012.

But the reason is a lack of customer knowledge and a small amount of market demand. The marketing of hollow bricks in Nepal has significant challenges due to a lack of national standards, adequate knowledge for producing hollow bricks, and soil preparation, according to Prajapati.

Why BEEN?

Through the development of circular economy techniques in the building sector, the BUILDING Energy Efficiency in Nepal (BEEN) project helps achieve the overarching goal of the European Green Deal (2019) and the EU Circular Economy Action Plan (2020).

By promoting green technology through capacity building, policy, and financial interventions, the initiative eases the transition to a low-carbon, resource-efficient, and circular building sector.

It is consistent with national pledges to reducing the effects of climate change, where the building industry plays a significant role.

In terms of promoting European standards in other regions, it also concurs with the new EU Standardization Strategy.

By making it easier to design, build, and renovate climate-friendly structures, the four-year project BEEN intends to support the growth of low-carbon and resource-efficient construction in Nepal's construction industry.

To further lower the building's carbon footprint, BEEN works to promote materials that are low energy and resource efficient during both their manufacture and use phases. The purposes because of the following, BEEN works to promote hollow bricks.

By encouraging climate-responsive building design, construction, and rehabilitation through the integration of energy efficiency and renewable energy measures, the BEEN Project seeks to assist in the achievement of low-carbon and resource efficiency in the Nepalese building sector.

In Nepal, solid-fired clay bricks are the most common type of building material. A niche product with minimal output is hollow brick.

Bricks are a crucial component of Nepal's exquisite architecture, especially the numerous historical sites in the Kathmandu Valley. In all parts of Nepal, solid-fired clay bricks are the primary walling material and are frequently employed in building construction.

Decarbonizing Building

Brick kilns use imported coal to fire bricks despite using locally available building components. According to a report, importing coal from India and other nations costs a significant amount of convertible currencies, or Rs. 25 billion.

Burning coal significantly increases air pollution and carbon emissions.

In these conditions, Nepal's net-zero greenhouse gas emission goal by 2045 will depend on decarbonizing the building sector.

By encouraging climate-responsive building design, construction, and restoration through the integration of energy efficiency and renewable energy measures, the European Union will help Nepal reach this goal through the four-year BEEN project.

BEEN Project facilitates the transition towards a low-carbon, resource-efficient and circular building sector through capacity building of micro, Small and Medium Enterprises (MSMEs), supporting the creation of enabling policy and financing environments and enlarging market share for energy-efficient and resource-efficient products and services.

Hollow Bricks Support Green

A product that uses less resources, hollow brick, is utilized all over the world. It is not yet a common product in Nepal, though. "Hollow bricks of various sizes conserve energy to varying degrees. According to research, fuel savings rely on the hollowness percentage.

According to studies, a brick with a 15% hollowness can save up to 24% clay and up to 30% fuel. According to Prajapati, a tubular hollow cavity improves insulation, which helps to lower energy costs for maintaining thermal comfort when operating buildings.

The study found that using and producing hollow bricks can dramatically save fuel costs for brick manufacturers, energy expenses for building occupants, and national economic benefits.

Brick kiln emissions are also reduced by the reduction in coal consumption.Its application results in a reduction in structural load in the building due to its lighter weight, which lowers the cost of building construction. The creation and use of hollow bricks are uncommon practices despite their enormous advantages on numerous levels. The low level of market demand can be ascribed to customers' lack of awareness.

Additionally, the marketing of hollow brick has not been helped by a lack of national standards and adequate know-how for producing hollow bricks.

With the help of Nepali stakeholders, the EU is launching the Hollow Brick Promotion Campaign through the BEEN Project in order to advance its larger objective of low-carbon and resource-efficient development. "The advertising campaign will be extended to other regions of the nation.

Hollow brick manufacture has also begun at another brick factory in Kapilvastu. BEEN will begin test production in another brick factory in Gandaki Province in collaboration with the Federation of Nepalese Brick Industries, according to Prajapati.

In addition to providing energy savings and improved thermal comfort for end users, the reduction of pollution is a benefit. For the producers, the users, the national economy, and the general public, it is a win-win-win situation.

In order to reduce the carbon footprint of buildings and establish a low-carbon and resource-efficient building construction sector in Nepal, hollow bricks are produced in the brick industry and used in multipurpose showcase buildings in the Lalitpur Metropolitan City.

Both visitors saw how hollow bricks are made in Harisiddhi and how they are used in a multipurpose structure in Gwarko, Lalitpur. With the support from EU, Nepal now enters to new phase of hollow brick. In the span of four years, the project will cover a lot of ground.

Keshab Poudel

Poudel is the editor of New Spotlight Magazine.

- KUL MAN GHISING: Bowing Down To The People

- Apr 13, 2025

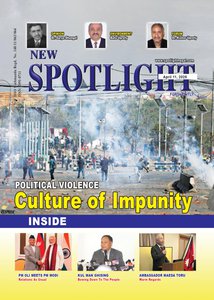

- POLITICAL VIOLENCE: Culture of Impunity

- Apr 11, 2025

- PM OLI MEETS PM MODI: No Progress

- Apr 09, 2025

- PM OLI’S THAILAND VISIT: Flip Flop

- Apr 08, 2025

- FM Dr. Deuba’s India Visit: Mission Aborted

- Mar 26, 2025